Everything You Need to Know About Custom Bottle Caps

Cap is an important part of the packaging closure system, through the cap and the container with effective cooperation, the formation of the product contents of the protective closed packaging, facilitates the production, circulation, preservation, and use of products, to convey the quality of information, the effect of packaging and the function of play a great impact. With the birth of various new commodities and the development of packaging technology, the market of packaging containers and their closure types is gradually increasing: spray bottle cap manufacturer, bottle cap manufacturers, child resistant caps manufacturer, and more.

Custom Bottle Caps and Neck Finish

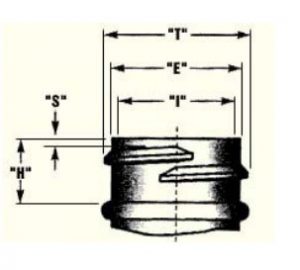

Bottle neck finish is very important when you looking for bottle cap manufacturers. Here we will see the dimensions of bottle neck finishes

T-Outside diameter of the continuous thread

E-Outside diameter of the finish shaft excluding thread

I-The inside diameter of the finish at the smallest possible point

S-The distance of the top of the finish to the top of the thread

H-Height from the top of the finish to the bottom where it intersects with the shoulder W-The thickness of the transfer bead(optional)

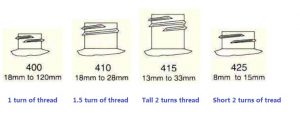

Standard plastic finishes most commonly used:

Standard Diameter of custom bottle caps: 20mm, 22mm, 24mm, 28mm, 33mm 38mm, 43mm, 63mm, 58mm, 54mm , 45mm

Standard Height of custom bottle caps:

Material and classification of Custom Bottle Caps

Material s of Custom bottle Caps are divided into: PP material, ABS material, sarin material, PTCG material, K material, electrochemical aluminum, etc., different material relies on touch sense, appearance, drop rebound sound, and other experience to determine, disinfection methods are not the same.

Inner lid: The inner lid should be complete, smooth, clean and not deformed. The inner lid should fit well with the bottle and outer lid. Inner The lid should not be missed.

Outer cap: The outer cap should be square, smooth, and without broken, cracks, or burrs (burr mouth). The color of the outer cap should be uniform and consistent. The color of the cover should be uniform. The threaded structure of the cover should be intact. The color and luster of the cover with aluminum electrochemical or gold stamping should be uniform. Flip type cover should be flexible, and the connection part No fracture. The cover and bottle should be tightly matched, with no slippery teeth, or loose.

Classic Types of Custom Bottle Caps

Non-Dispensing Custom Bottle Caps- Screw cap

Screw Cap

This type of cap includes ordinary screw caps, screw caps for vacuum sealing, lug caps, pressed caps, crown caps and rolled caps that matches the container of gas containing the beverage. It is possible to complete the sealing of the packaging container in the production of the product, and ensure the convenience and effectiveness of opening and repeated closing when the consumer uses the product.

Our widely used anti-theft threaded caps are composed of two structures: caps and anti-theft rings.

The cap mainly consists of a non-slip screw cap tooth line, a sealed inner stopper to prevent liquid leakage, and a thread inside the cap.

The cap is fastened to the bottle mouth by matching the mouth of the bottle and is designed to prevent the leakage of substances inside the bottle, as well as the intrusion of outside

The cap is fastened to the mouth of the bottle by fitting the mouth of the bottle. When the cap is tightened, the mouth of the bottle penetrates deep into the top of the cap to the gasket, and the inner groove of the mouth of the bottle and the threads of the cap are in close contact with each other to seal the bottle.

The threads of the cap are in close contact with each other, providing pressure to the sealing surface.

The several sealing structures can effectively avoid the leakage or deterioration of the bottle contents.

Childproof cap

child resistant caps manufacturer

Smart caps are mostly used in the packaging of food, drugs, chemicals, etc., which require high consumer safety, and are being used more and more widely. In modern society, the security of open-shelf goods (original seal, reliable quality), and pharmaceutical packaging safety precautions (to prevent children from opening but not to prevent other people from using them) is increasingly important.

Child resistant caps manufacturer has certain regulations or restrictions on the opening method, such as after being opened can be left to indicate that the seal has been broken traces of open (anti-theft) cover, open when the need for certain children have difficulty achieving the strength or complex movements of childproof cap from Child resistant caps manufacturer.

Dispensing Caps

These caps are distribution (diversion) caps, pouring caps, coating caps, spray bottle cap manufacturer, etc., which can meet the special requirements of powder, flake, granule, liquid, and gas-liquid mixture when using the contents – such as the outflow can be controlled, easy to squeeze out, easy to pour, can be sprayed, etc.

Classification of dispensing pumps

1. pump according to the cap (pressure head) opens in different ways and can be divided into screw-type pumps, card-type pumps, and left and right lock pumps.

The pumps can be classified as screw type pumps, card type pumps left and right lock pumps, hand buckle-type pump (spray gun), with the outer cover of the direct press type pump and with the outer cover of the left and right lock pump. Snap-on pump cap

Mainly used for cleaning products, such as grease removal and glass cleaning products.

2. pumps can be divided into emulsion pumps, foam pumps, vacuum pumps, spray pumps (nozzle), air pump (spray) , etc. according to the function. Spray pump (spray) , etc.

Lotion pumps and spray bottle cap manufacturer

spray bottle cap manufacturer

Twist Tip Caps

foaming pumps

Flip caps, Disc Caps

Tips for Custom Bottles Caps and Pumps

1. The size of the custom bottle caps is determined by the caliber of the matching bottle,

the specification of the spray is 12.5mm-24mm, and the water output is 0.1ml/time -0.2ml/time, generally used for perfume, gel water, and other products on the packaging with the same caliber receiver.

2. Emulsion pump specifications range from 16ml to 38ml, the water output is 0.28ml/time – 3.1ml/time, generally used for cream and detergent products.

3. Special dispensing custom bottle caps such as foam pumps and hand buckle nozzles, the foam pump is a non-gas-filled hand pressure pump. The foam pump is a kind of non-filled hand pump, with no need to fill the air to produce foam, only need to lightly press to produce a quantitative high-quality foam. It is usually equipped with a special The pump is usually equipped with a special bottle. The hand-clip nozzle is usually used on products such as detergents.

4. The composition of the dispensing custom bottle caps is more complicated, generally including a dust cover, snap cap, snap rod, gasket, piston, spring, valve, cap, and pump. Spring, valve, cap, pump body, suction tube, valve ball (with steel ball, glass ball). Bottle cap, dust cover Cap can be colored, can be plated, can be set electrochemical aluminum ring.

5. Because a set of pumps involves more molds, the minimum order quantity from bottle cap manufacturers is 10,000-20,000, and the delivery period is 15-20 days after confirming the sample, white and universal types are often.

6. White and general types are often in stock from bottle cap manufacturers or spray bottle cap manufacturer.

7. The dispensing cap customers rarely open their own molds, and the molds they need are more expensive.